Description

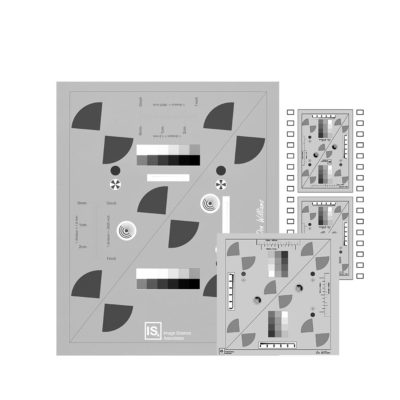

The DT Next Generation Target, Version 2, or DT NGT2 for short, is a professional-grade color reference target. It serves the same kind of purposes as an X-Rite Color Checker SG, but with significantly higher precision, accuracy, durability, and build quality. Originally designed at the behest of the Library of Congress, the NGT2 is now available to Digital Transitions clients seeking the most robust, accurate, and precise color reference target available anywhere.

Common Users

Color reference targets are commonly deployed in color-accurate photographic workflows. For example, in cultural heritage settings such as museums, libraries, and archives, it is important that the color in an image of a collections object such as a vase, painting, drawing, or letter is accurate to the original physical object. In commercial studio environments, color accuracy means consumers better understand the color of an item they are purchasing which decreases returns and increases customer satisfaction. In scientific and research settings insert link color accuracy and precision are often critical in using images of physical objects as sources of quantifiable data. In short, wherever there is a need for accurate and precise color, color reference targets are essential.

Common Uses

Color reference targets are used to measure, analyze, and improve the accuracy of color in a photographic or imaging workflow. This includes the creation of custom color profiles, checking and quantifying the color accuracy of an imaging system, validating that an imaging system complies with required color quality specifications such as those found in FADGI, Metamorfoze, and ISO 19264. They can be used both numerically (via analysis of the resulting color values in RGB or LAB), programmatically (using software such as Golden Thread, OpenDICE, or BasICColor), or visually (by comparing the target to an on-screen image on a color-calibrated monitor such as an Eizo.

In addition to these frequent tasks, the quality and durability of the DT NGT2 makes is an excellent master reference against which consumer-grade color targets such as the X-Rite Color Checker can be measured for drift/aging/degradation. Ideally, all targets in the workflow would be DT NGT2 targets as this has significant advantages over the use of consumer-grade targets.

Color Accuracy

The most important element of any color reference target is the distribution, precision, and accuracy of the color of its color patches, and in this the DT NGT2 is unrivaled. The 130 patches have been methodically selected to evenly cover the color space described by the glossy Munsell Book of Color with special attention to the hyper-critical skintone and papertone colors that are common in both Cultural Heritage collections and fashion photography. The center 24 patches replicate the familiar 24 patch pattern of consumer Color Checker charts. Finally, there are repeated black and white patches to help check for illumination uniformity and geometry. Each target can be delivered individually measured by a NIST-traceable spectrophotometer, providing complete assurance that you have the exact measured values of your specific target.

Handling and Cleaning

Also unrivaled is the DT NGT2’s robustness to real-world handling. With consumer-grade color reference targets the perils of everyday handling, even by careful users, quickly deteriorate the accuracy of the color patches. For example, a small amount of finger grease, dust, sputum, or other environmental contamination can wreak havoc on the glossy patches of a Color Checker SG. This is compounded by the fact the color patches in a consumer-grade target are fully exposed making cleaning ill-advised, as even careful cleaning may further damage the patch. Imagine trying to manufacture consistently-sized lumber with a ruler that stretched unpredictably during normal use; using a color reference target that gets dirty easily, and is hard to clean, presents the same challenges.

These issues have been carefully and thoroughly addressed with the design of the DT NGT2. First, every patch is encapsulated in a carefully selected transparent film that abates wear and tear from normal handling by reducing the patches’ exposure to the environment, and allows the target to be cleaned of normal soiling without damaging the target or affecting the accuracy of its patches.

Build Quality and Geometric Precision

Consumer-grade color reference targets are constructed of non durable materials such as cardboard and light plastic. This has three practical ramifications. First, the shape of such targets often become misshapen over time, for example bending into a U shape, especially if the humidity and temperature of the room are not entirely static. Second, even before/without such warping each color patch is far from precisely parallel to the working surface which can lead to measurement errors that are especially problematic when generating new color profiles. Third, they are not durable over time and tend to tear, warp, or bend with normal usage.

A target whose patches are not parallel to the camera will read erratically, especially if those patches are glossy as they are in the case of the Color Checker SG. This can lead to very significant deviations, particularly in darker patches which will inappropriately pick up specular reflections of the light sources. Such issues are immediately visually obvious when the chart is significantly bent or warped with time, but can even cause issues on a brand-new seemingly “flat” consumer-grade target due to the poor quality of construction and imprecise seating of the patches.

The DT NGT2 is manufactured from a solid piece of aluminum milled to 0.001” (40μm) precision; this totally prevents warping from humidity and temperature variation, and makes the target exceptionally durable to normal handling. Each and every patch is individually laid, individually measured, and individually calibrated to be exactly parallel to the metal backing.

Finally, all DT NGT2 targets are delivered in a foam-lined latching case ideal for long-term storage when not in use, further bolstering its longevity and useful life. While an DT NGT2 may be initially more expensive, its incredible physical durability, along with the cleanability of its color patches make it a far better long-term investment.

Measurement and Serialization

The DT NGT2 is manufactured with extremely tight tolerances. That is, every DT NGT2 has color patches that are almost identical in color to any other DT NGT2 (such nominal values are published here). However, when creating and validating color profiles in high-end applications (such as compliance with FADGI 4-star Preservation Grade standards) even very slight variations from one target to the next will matter. In such cases, each target should be individually measured. You can do this yourself (provided you have the equipment, expertise, and time) or you can purchase the DT NGT2 target pre-measured. This is the NIST Traceable Custom Measurement option shown at the top of this page. That requires a 2-week lead time. The measurements will be made by an expert in metrology, using a bidirectional (45:0) spectrophotometer, reporting spectral reflectance (with measurement-confidence interval) and CIELAB calculated using illuminant D50 and the 1931 2° standard observer. The CIELAB data will be formatted as comma-delimited CSV file. For other illuminant/observer or reporting options or more information about the traceable measurement process please contact us.

All DT NGT2 targets are labeled on their front with an individualized serial number, so that they can be easily identified now and in the future.

Calibration and Purchasing Options

You have several purchasing options with the DT NGT2:

- DT NGT2 With Traceable Measurement [DT-NGT2-NIST]

- DT NGT2 With Additional Reporting Options for NIST Traceable Measurement [DT-NGT2-CR]

- DT NGT2 Traceable Measurement Only (target not included) [DT-NGT2-TDF-NIST]

- DT NGT2 Without Traceable Measurement

What is DT NGT2 Traceable Measurement?

This is a professional measurement of your specific physical target. It can be purchased at the same time as the physical target (in which case we measure one and ship it to you), or it could be purchased as a separate service for someone who already owns a DT NGT2 target. For example, an institution might purchase this service once per year to make sure they are using the most up-to-date values for that target as it slowly shifts over time. This report will be in CIELAB calculated using illuminant D50 and the 1931 2° standard observer. For additional reporting options, the user must purchase DT-NGT2-CR.

What are the Additional Reporting Options for NIST Traceable Measurement?

This is an add-on to an order for DT-NGT2-TDF or DT-NGT2-NIST and is typically purchased at the same time as one of those. It allows the user to receive an additional reporting option such as a different illuminant/observer or output format for the NIST Traceable Measurement (which otherwise is reported only as CIELAB calculated using illuminant D50 and the 1931 2° standard observer.

Additional Information

The Digital Transitions Next Generation Target v2 is built to be a precise and robust target designed to withstand daily use and accidental grime. To ensure these standards each target is hand tested. As a result of testing there may be superficial scratches that become visible under direct specular light. These superficial scratches should not be visible from a camera under normal illumination (30-45o illumination, camera directly overhead) and do not affect the accuracy of the target.

Digital Transitions stands behind its products. If there are any concerns over more distinct marks on a DT NGT v2, DT will be happy to review or replace as needed.