DT Film Scanning Kit

- Integrates with DT Atom, DT Element, & DT Versa

- Optimized workflow with Capture One CH

- Easy to operate

- Extremely durable for years of continuous use

The DT Film Scanning Kit (FSK) revolutionizes film digitization with speeds over 400 times faster than legacy equipment, significantly reducing both scanning and post-production time. It delivers high-speed, FADGI 4-Star compliant scanning at up to 7000 ppi, with a capture speed of less than one second for any film size. Designed for rapid capture, the FSK uses steel carriers and a magnetic mask to hold film in place, with user-replaceable masks available as service items. This makes it an economical solution for institutions with diverse film formats. Ensuring conservation handling, the FSK supports contact-free scanning, allowing operators to handle materials safely without automatic machine feed mechanisms. Combining unparalleled speed and quality, the DT FSK meets and exceeds FADGI 4-Star and Metamorfoze imaging standards.

DT Stellar

The DT Stellar provides the highest-quality, most consistent illumination on the market for both reflective and transmissive materials. It features a custom LED pane achieving 98 CRI-14, 98 CQS, and 98 TM-30-18-Rf with a smooth, UV-free spectrum. DT includes bespoke ICC profiles with the Stellar for all its cameras, ensuring FADGI and ISO-compliant color quality out of the box. Designed for high-volume workflows, the Stellar is color-stable within 10 seconds of powering on, and its active cooling system maintains consistent color temperature and brightness. Self-contained for flexibility and mobility, it requires no external control box, and its built-in power adapter simplifies cabling and operation. The Stellar ensures material safety, emitting no UV radiation and maintaining controlled temperatures, making it safe for both reflective and transmissive materials. Ergonomically designed to reduce eye fatigue, it dims automatically between captures and features optional hoods to limit visible light and camera flare. Built in the USA with industrial-grade standards, the Stellar comes with a three-year parts and labor warranty and is designed to last decades. Supported by DT’s award-winning expert support team, it adapts to various digitization needs, with each unit suitable for reflective or transmissive materials.

DT Gemini – Twin Lights

For larger stations like the DT Element, DT Versa, or DT Titan, two Stellars can be combined using a DT Gemini Kit creating a 96cm (38″) light similar in form factor to a DT Photon XL, but with significant ergonomic improvements. The Gemini bracket centers the weight of the lights over the stand, and pivots the lighting up or down without changing its balance or distance to the subject.

DT V-Cradle

Bound Material Digitization, Ergonomic Precision Scanning, Customizable Book Capture

Best for:

- Standard Bound material

- Books

Ideal for these types of Institutions:

- Rare Book Collections

- Libraries

Integration:

- Integrates with DT Atom, DT Element, and DT Versa

More information:

The DT V-Cradle emerges as the quintessential solution for streamlining the digitization process of bound materials, prioritizing simplicity, speed, and safety. Developed through extensive collaboration with the Cultural Heritage community, it addresses specific needs such as handling rare and delicate materials, accommodating various bindings, and seamlessly integrating into diverse workflows. Complementing the DT Atom, DT Versa, and DT Element, this cradle facilitates preservation-grade digitization of A3 bound materials (up to 17” x 12”), boasting a tilt-inward mount for ergonomic operation without expanding the system’s footprint. Its adjustable cradle offers three book-opening angles (100°, 180°, and 80°), ensuring optimal handling of diverse materials. The removable glass, equipped with a lift-assist mechanism, enhances user ergonomics, with quick removal options available to suit material requirements. Furthermore, meticulous design features, such as a sliding mechanism for the book platform, guarantee proper alignment and mitigate pressure on bindings, ensuring meticulous attention to detail and the preservation of precious collections.

DT Reel Film Top

The DT Reel Film Top enables DT Atom users to scan various reel film sizes, from microfilm to large-format aerial film. It provides 14k scans at 16-bit quality, exceeding FADGI 4-Star, ISO 19264, and Metamorfoze imaging standards. Designed for safety, it handles damaged, deteriorating, or invaluable reel film securely. Built for industrial use, it can hold heavy reels and endure years of heavy use. Its modular design allows selection of appropriate reel sizes, supporting film up to 12″ wide, 16″ in diameter, and 10 lbs in weight, and as small as 8mm motion film or microfilm. Manual feed and uptake are facilitated by smoothly rotating hand controls, with customized reel carriers included. All surfaces are easily cleaned, and the adjustable film path height maintains precise planarity, essential for fragile film. Optical quality glass ensures museum-grade clarity, and a customizable locking gate blocks stray light.

- Integration with the DT Atom

Quality Control Accessories

In today’s fast-paced digitization landscape, efficiency is key. DT offers various Quality Control Products to help streamline your workflow and ensure top-notch results.

Targets

Color reference targets are commonly deployed in color-accurate photographic workflows. For example, in cultural heritage settings such as museums, libraries, and archives, it is important that the color in an image of a collections object such as a vase, painting, drawing, or letter is accurate to the original physical object. In commercial studio environments, color accuracy means consumers better understand the color of an item they are purchasing which decreases returns and increases customer satisfaction. In scientific and research settings insert link color accuracy and precision are often critical in using images of physical objects as sources of quantifiable data. In short, wherever there is a need for accurate and precise color, color reference targets are essential.

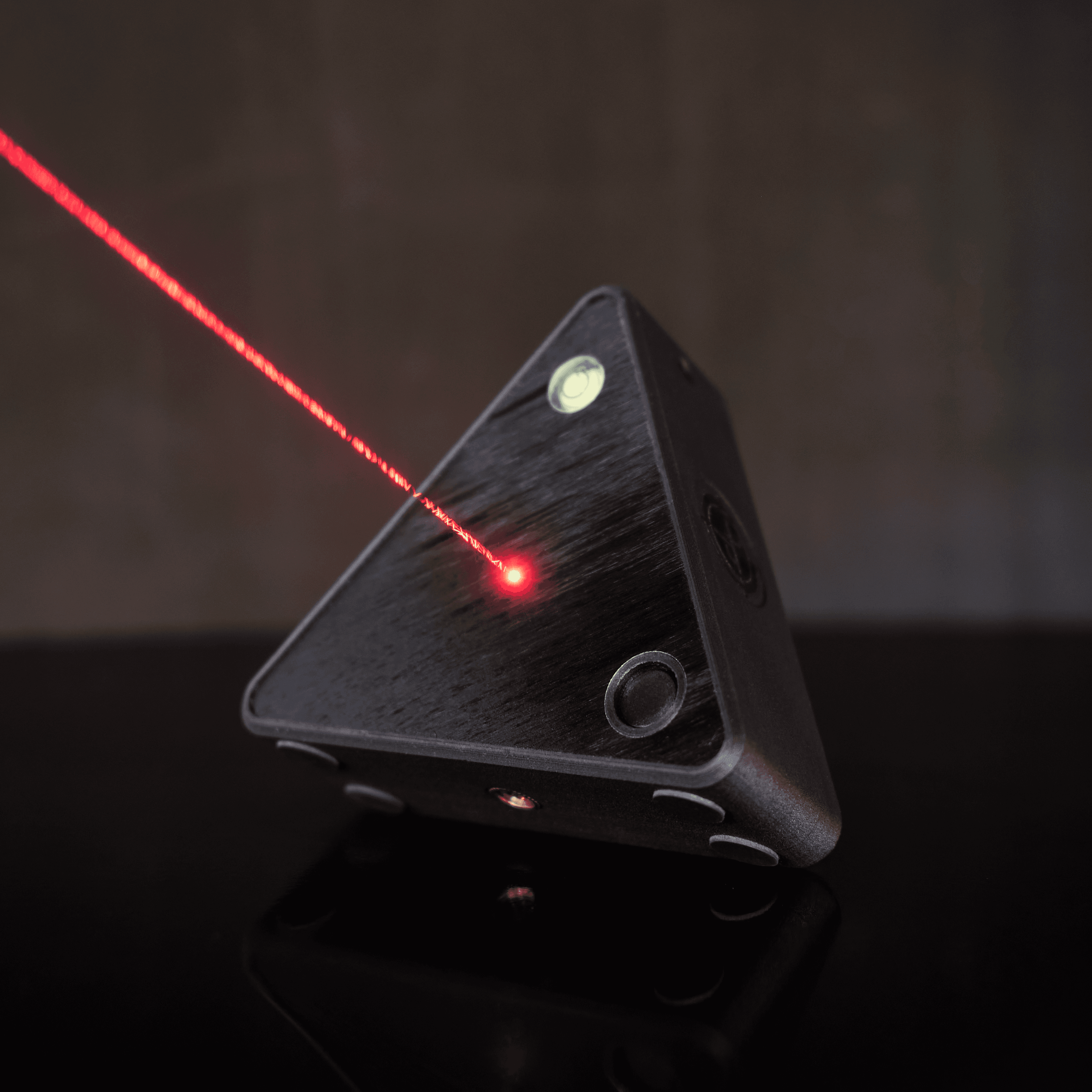

DT Laser Align

The DT LaserAlign is a precision-built laser alignment system designed for the Heritage community, offering unmatched accuracy, durability, and functionality for the most sensitive applications. Ensuring compliance with FADGI, Metamorfoze, and ISO 19264 standards, it features a triangular design for stability, a thermally stable carbon-fiber composite body to prevent warping, and padded feet for safe contact with delicate surfaces. Its precision laser has the smallest spot size available and is hand-calibrated at the factory to a 0.025-degree tolerance for exact perpendicular alignment. The DT LaserAlign also includes a magnetic base for angled surfaces, a tripod thread and spirit level for imaging art on walls or easels, a hanging hole for special applications, recessed controls for transit durability, and a USB rechargeable battery. The laser is exactly centered, simplifying calibration checks by rotating the device around the laser’s center.

DT’s QC Webinar

Check out our QC Workflow Webinar. Whether you’re a seasoned digitization professional or just getting started, this webinar is your opportunity to stay ahead of the curve and elevate your QC game to new heights.

DT Digitization Training

DTDC 101: Intro to Modern Digitization

Digitization has undergone a rapid and profound transformation in the past two decades. Legacy systems built on scanning have been replaced with modern instant capture systems. Direct-to-TIFF workflows are being replaced by RAW workflow. Institutions are adopting FADGI and other guidelines that ensure digitization is done at a preservation-grade of quality, but require a more nuanced understanding of image quality than relying on manufacturer’s stated PPI. To fully reap the rewards of this transformation requires new hardware, software, and workflows, as well as a new approach to digitization’s position in an institutional context. In this class we’ll take the 10,000 foot view of these transformations to form a foundation of the modern approach to digitization.

DTDC 201: Operator Training

This course covers routine workflows for camera-based digitization systems, from capture to post-processing. It covers topics like setting exposure, establishing focus, creating an LCC (even field), as well as topics like file organization, batch editing, and batch processing. Also included are basic standards-compliance theory and image-quality evaluation, including FADGI, ISO 19264, Golden Thread, and OpenDice. Students emerge ready to be operators of modern digitization systems for most non-challenging object types.

DTDC 301: ICC Profiles

Custom ICC profiles are one of the most complex and precise workflows that we come across in Heritage Imaging. It is very important to understand the complete process, why we are creating these profiles, and how we know the profiles are accurate, before baking them into an existing high quality production workflow. In this course, we will advise on best practices for an entire end to end workflow for using a RGB camera to digitize color materials. System preflight, capture, processing and evaluation will all be touched upon. This course heavily features Capture One, BasICColor and Golden Threads software, along with the Golden Thread and DT NGTv2 color targets. This target and software methodology is the most widely used in digitization programs.